Dispersion

The homogeneous distribution of pigments and other solids is one of the most time- and energy-consuming processes in the coating production. This aim is quite often achieved only with difficulties. However, the quality of the pigment dispersion is strongly influencing essential coating properties: colour strength

- hiding power

- gloss

- weather resistance

- mechanical properties

The difficulties are the different surface tensions of the various components. These tensions have to be adjusted to an approximately similar level of all components. In this process

dispersing additives are indispensable.

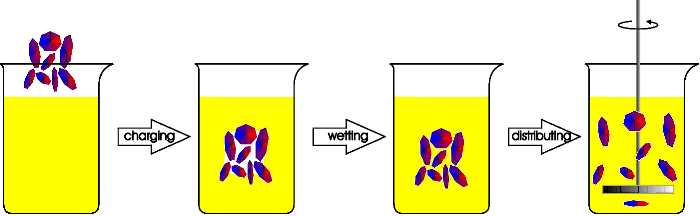

The dispersion process

- The pigment which normally is a powder has to be incorporated into the liquid phase, i.e. it has to be wetted by it (conversion of the boundary layers solid/gaseous into solid/liquid).

- The existing agglomerates have to be converted into primary particles.

- These primary particles have to be uniformly distributed into the system.

- This uniform distribution has to be stabilised as long as possible.

The dispersion process aims at the complete splitting up of the agglomerates and the regular distribution of the primary particles in the system as well as the long lasting stabilisation of this state. Both points are of the same importance: In practice an optimum distribution of the pigments has to last until the coating is applied.

Pigment wetting

Commercially available pigment powders contain a large amount of air in spaces between the agglomerates, i.e. to two-thirds of its volume on average. During the wetting process this amount of air has completely to be replaced by the liquid phase. In most cases, the adsorption energies of the solvents and binding additives used are too low in order to guarantee this process sufficiently. The wetting of a surface will only be made if the surface tension of the wetting additive is lower than of the surface to be wetted.

This means the surface tension of the liquid phase of a coating system has to be clearly lower than that of the pigments in order to wet the pigments effectively. Dispersing additives will also ensure it.

Grinding of pigments

This is achieved by using mechanical dispersing units. By high shear forces the interaction of the individual particles is resolved and thus the wetting of the particles is supported resulting in separation of the agglomerates. This stage is very susceptible to new agglomerations first and therefore it is important to stabilise it at once.

Stabilisation of the dispersion

Preventing the particles from agglomerating during production and storage is one of the main functions of dispersing additives. They also have to neutralise the attraction between the particles.

Action of dispersing additives

Dispersing additives will adsorb on the surface of the pigments and will thus fulfil the function of a “distance holder”. In this context the term of steric hindrance is established. Nowadays most of the dispersing additives will work according to this principle. Another method is the electrostatic stabilisation. However, its importance is decreasing in our days. The blue balls in the illustrations show the particles encapsulated with the dispersion additive.

Dispersing additives can roughly be divided into two categories. Low molecular dispersing additives with tenside structure and polymeric dispersing additives with different anchor groups in a longer molecular

chain:

Divided up again rather roughly the low molecular dispersing additives are more used with inorganic pigments and for organic pigments often a combination of low molecular for wetting and polymeric for stabilisation is used. The surface character of inorganic pigments is rather similar. As a rule they are built ionically and are strongly polar on their surfaces. In this case the dispersing additive with classic tenside character can adsorb relatively easily.

In case of organic pigments covalent surfaces are more frequent. They might be chemically very different from each other depending on pigment. In this case polymer dispersing additives will often offer the advantage of a higher amount of (different) anchor groups in order to adsorb well on the different pigments surfaces in the same way. Since the beginning of paint production polymer dispersing additives of a natural origin (albumen, gum arabic) have been used. In the past decades the production of purely synthetic dispersing additives was finally started. They were first developed for organic pigments which are difficult to wet, but can also be used for inorganic pigments. Due to their universal possibilities of use especially in case of pigment pastes polymer dispersing additives have been strongly favoured in the past years. The low molecular dispersing additives were sometimes regarded as old-fashioned and out-dated.

However, both groups offer their special advantages and disadvantages and in many cases the classic means will serve its purpose in quite the same way just like the "modern" polymer products. In both classes the desired effect is reached via the same mechanisms, mainly via the so-called steric hindrance or electrostatic repulsion.

Low molecular dispersing additives have to be selected depending on kind of pigment used, i.e. they are not always suitable for all pigments. When using polymeric dispersing additives it is necessary to look for attention to a good compatibility. In order to be effective, the polymer chains have to be untangled. Furthermore they have to be well compatible with the surrounding medium (i.e. first of all the resin). A limited compatibility will lead to an entangled state of the polymer chains, resulting in decreased pigment surface coverage or even none at all.

Especially in the aqueous medium the wetting effect of additives is very important besides the dispersing effect, due to the high surface tension of water. The stabilisation by electrostatic repulsion is becoming more important. In this sector the classic dispersing additives have regained in importance again even with high-quality systems.

By combining different tensides skilfully or by using classic tensides in combination with polymer additives it is now possible to combine the advantages of one class with those of the other. With this method additives are obtained which will supply good results in a great variety of different systems and with a large variety of different pigment mixtures. Especially the universal pastes which are increasing in importance demand a high degree of universality of the dispersing additive.

Bernd Schwegmann GmbH & Co. KG describes in separate brochures a wide range of wetting and dispersing additives.

Product range by Bernd Schwegmann GmbH & Co. KG

| Solvent-based systems: |

SCHWEGO® wett 6248, 6264, 6267, 6291, 8081, |

| Solvent-free systems: | SCHWEGO® wett 6264, 6267, 6295, 8092, 8319 |

| Water-based systems: | SCHWEGO® wett 6291, 6292, 6295, 8319 |

| Tinting pastes: | SCHWEGO® wett 6264, 6267, 6291, 6295, 8081, 8085, 8319 |

| UV - paints: | SCHWEGO® wett 6292 |

| Printing inks: |

SCHWEGO® wett 6264, 6267, 6295, 8083 |

| Universel additives: | SCHWEGO® wett 6292, 6264, 8319 |

| Bio-based paints: |

WETT AGENT, WETT AGENT 8023, SCHWEGO wett 6295, 8319 |

The quality of a dispersing additives can also be determined by relatively simple methods:

One method is the determination of the grinding fineness e.g. by means of a Hegman block, in which the fineness of the particles can be determined after a certain dispersing time. The disadvantage is that only the coarse particle sizes are recorded, but not the particle size distribution. Also opacity (hiding power), colour shade and gloss are essential characteristic properties, which are measured and evaluated by applying a defined layer thickness, for instance on a morest chart.

Another very simple and meaningful process is the so-called “rub-out-test”, which shows the floating behaviour of pigments in coating films. The rub-out test describes the colour change which will take place when rubbing at a nearly dried part of the coating in comparison to the non rubbed part. If the distribution of pigments in a coating is not homogenous, by rubbing the distribution is restored again to a homogeneous stage. By high viscosity of the varnish layer, a renewed separation until the layer will be finally dry is not possible any more. The quality of the pigment distribution and stabilisation is determined from the difference in colour tone and consequently also the effectiveness of the dispersing additive.