Defoaming / Deaerating

The growing requirements at the paint developer to optimize his formulation in environmental (reduction of organic solvents, free of VOC, free of APEO….) and also in economical view is the starting point for the raw materials supplier to find always new solution to fulfill this new requirements.

It was also in the area of defoamer necessary to develop new products, because sometimes the old products did not fulfill the new environmental demands or they did not work in the new kind of resins and emulsions. The choice of the right defoamer is very important and offers advantages in the production of the paint, at the application and in the optic of the dry paint film. So it is possible to improve the expensive grinding process, to avoid troubles at the filling of the paint and to prevent surface defects like pinholes or crater in the dry paint film with the right defoamer.

What is foam? How to get foam?

By the current state of view, foam is a thermodynamic unstable two-phases-system of rough distributed gaseous in liquid or solid medium.

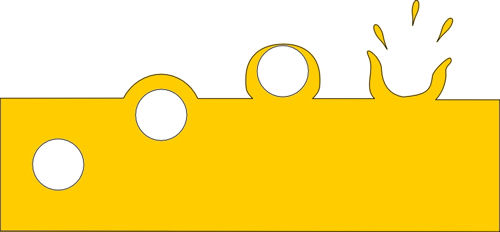

Pure liquid do not foam. During shaking of pure water bubbles (sphere foam) occur inside of the liquid, the bubbles rise at the surface of the liquid and break (fig.1).

fig. 1

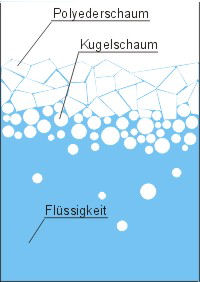

If there is a stabilization of the bubbles at the surface of the liquid, the sphere foam deformed above the boarder of the densely sphere packing to polyheydral foam (fig.3).

The speed of the bubble to achieve the surface of the liquid depends on the viscosity and the diameter of the bubble (Law of Stokes).

As per description foam is in pure liquid thermodynamic unstable. This statement is in contrast of the daily practice in the paint world. Normally paints are not pure liquids. Surface active substances are inside to achieve special properties.

So it is necessary to use emulsifier for the production of the polymer emulsion. Additives like dispersing agents, substrate wetting agents or leveling agents are in use to achieve special paint properties or to improve the process at the production.

Surface active substances like emulsifiers are dipole with hydrophobic and hydrophilic centers. In nonionic types the polyether from ethylene oxide with different molecule length could be the hydrophilic part and the hydrophobic counter pole could be a fatty alcohol or a fatty acid.

These products are able to concentrate at the interface liquid / air or to build micelles in water in doing the orientation of the hydrophilic part (under reduction of the surface tension) in direction water and the hydrophobic part in direction air. This means, if you get air in a liquid with surface active substances, the orientation of the surfactant will be at the interface liquid / air at the surface of the liquid and at the bubble (fig.2)). If these bubbles reach the surface, which also coated with surfactant, a surfactant-stabilized double layer is formed.

fig.2

Initiator for foam troubles in the paint industry could be following parameters:

- Production - Grinding- and Mixing process, Filling of the paint

- Application - Spraying (Airless, Airmix… ), Curtain coating, Brushing, Rolling

- Chemical reaction - Two pack coating systems

- Substrate - Wood …

- Paint parameter - Viscosity, Rheology profile, …

The coating industry is always looking for solutions to prevent micro foam or macro foam. Normally micro foam is more a problem in solvent-based or solvent-free, but also in aqueous formulations with low PVC. Macro foam is more usual in aqueous systems. The task of defoamer and deaerator is to prevent this kind of foam, whereat defoamer act more against the foam at the surface of the liquid (macro foam) and deaerator speed up the bubble (micro foam) in the wet film, so that the bubble can leave the film before drying. But in the praxis it is normally not possible to differentiate clearly between defoamers or deaerators.

fig. 3

|

|

Effictiveness of defoamers

The defoamer must be insoluble in the formulation to be defoamed. It must penetrate very quick to the foam lamella, must spread on this and must destroy this. In the market it is normal to classify the different types in mineral -, white-, silicone oil or polymer defoamer. These are the carriers, with the task to transport the active substance as quickly as possible to the foam lamella (entering coefficient) and to spread (spreading coefficient) on this. The active substances such as silica absorb the surfactants from the foam lamella to get a destabilization and in ideal case a destroying of this. Naturally carrier has an antifoam effect too, but this is very often not good enough to fulfill the requirements from the paint industry.

Examples of carries

• mineral oil

• silicone oil

• white oil

• polymere

• native oil

Examples of active substances

• silica

• wax

• urea

• metal soap

The properties of above mentioned classes of products can be roughly abstract in following table:

(depending on the system)

| mineral oil white oil native oil |

silicone oil | polymere | emulsion | |

| efficiency | good | very good | very good | good |

| long term stability | good | good | good | moderate |

| incorporation | moderate - good | moderate - good | good | very good |

| gloss / haze | moderate | good- moderate | good | depending on type |

As per description defoamer should be insoluble in the system to be defoamed, but the incorporation should be possible with low shear performance and without influence onto leveling (crater), gloss or haze in the different coatings. The efficiency should be not less after long storage of the paint.

Schwegmann has a wide range of defoamer / deaerator for solvent-based, solvent-free and aqueous formulations. They are based on mineral oil, natives oil, modified silicone oil and polymers. Furthermore you can find 100% products, but also types diluted in organic solvent or emulsion to improve the incorporation.

The first step was the development of our VOC free/poor defoamer SCHWEGO® foam 6303, 6354, 6375 und 6388 for paints with low VOC content. These are further developments our old approved BLISTER FREE – types. Beside the reduction of the VOC content, it was possible to improve the efficiency from the new types. See the test results in long oil alkyd resin (fig.4) and acrylic resin, OH- functional (fig.5).

SCHWEGO® foam 6305, 6390 und 6391 are new defoamer emulsion types, developed especially for aqueous coatings. They prevent micro foam and macro foam. The application fields are high gloss paints, matt to satin-gloss emulsion paints, clear coats, wood - and industrial coatings.

SCHWEGO® foam 6360 und 6361 are deaerator special for UV – coatings. These products are able to crosslink at the UV drying process and do not disturb the film.

Test methods for the judgement of defoamers:

Density test

The complete formulation (with/without defoamer) is stirred with a dissolver under defined parameters (time, rotation speed …). After the stirring step measure directly the density with a density bottle. Best efficiency is the product with the highest density.

Compatibility test

The paint is applied with a doctor blade (defined thickness) on glass. After the drying of the paint measure the influence of the defoamer on gloss, haze and leveling (crater, fish eyes).

Volume test

Air is supplied in the system by stirring or shaking under defined conditions. Thus the resulting total volume is determined. Furthermore the time-dependent foam reduction is observed.

Coating test (Roller test)

The paint (defined amount) is applied with a sponge roller to a substrate. Micro- and macro foam can be evaluated on the dried paint film.

Long term efficiency

Store the paint 21 days at 50°C (or 40°C, depending from the emulsion) and repeat the density test and coating test. The test results should be equal to the first (directly) results. If not, the dosage of the defoamer is too low in this system.

Test results of our defoamers in different systems

The results are demonstrated in volume % air, means we calculated the amount of air, which we got after a defined stirring time. Best efficiency is the defoamer with the lowest content of volume % air.

fig.4

Test results in a long oil alkyd resin

Resin: Setal AF 681 (Nuplex Industries Ltd.)

Dosage: 0,5% defoamer / resin

Test method: 10 minutes stirring at 4000 rpm

BF = BLISTER FREE, SF = SCHWEGO® foam

fig.5

Test results in an acrylic resin, OH – functional

Resin: Setalux 1151 XX-51 (Nuplex Industries Ltd.)

Dosage: 0,5% defoamer / resin

Test method: 10 minutes stirring at 4000 rpm

BF = BLISTER FREE, SF = SCHWEGO® foam

fig.6

Test results in a high gloss emulsion paint based on an acrylic emulsion, self-crosslinking

Dispersion: Neocryl XK 98 (DSM N.V.)

Dosage: 0,5% defoamer / paint

Test method: 5 minutes stirring at 4000 rpm

SF = SCHWEGO® foam

fig.7

Test method: coating test with the sponge roller

SF = SCHWEGO® foam

fig.8

Test results in two satin-gloss paints based on a styrene / acrylic dispersion and a vinylacetate / vinylversatate dispersion (MFFT of both: 2°C)

Dispersion: Ecrylic KD 790 (S/A-type) / Ecrovin LV 485 (VA-type) (Michelmann)

Dosage: 0,5% defoamer / paint

Test method: 5 minutes stirring at 4000 rpm

SF = SCHWEGO® foam

fig.9

Test method: Coating test with the sponge roller in a satin-gloss paint (Styrene / Acrylic – dispersion)

SF = SCHWEGO® foam

fig.10

Test method: Coating test with a sponge roller (Vinylacetate / Vinylversatate – dispersion)

SF = SCHWEGO® foam

fig.11

Test results in an aqueous wood primer based on a cationic alkyd emulsion

Emulsion: Necowell 4400 (ASK Chemicals)

Dosage: 0,5% defoamer / paint

Test method: 5 minutes stirring at 4000 rpm

SF = SCHWEGO® foam

It is not possible to find one product with real good efficiency in all different kind of formulations. The reason is the complexity of the different paint formulations which you can find in the market. The best is always to find the right defoamer for the formulation with determined work.

Summary of test results

The VOC free / poor defoamer SCHWEGO® foam 6303 / 6354 / 6375 und 6388 are slightly better in the density test compared with our standard products. SCHWEGO® foam 6375 achieve in both resins very good efficiency against macro foam, but also in coating test is the deaeration effect very quick. Application fields of SCHWEGO® foam 6375 are high-solid-house paints, NC-lacquer, furniture coatings.

SCHWEGO® foam 6305 is a polymere type for aqueous formulations. It has universal properties and prevents micro - and macro foam in different kind of formulations. Application fields are high gloss paints based on pure acrylic dispersion or alkyd emulsions, but also in solvent-free satin-gloss emulsion paints, wood- and industrial coatings.

SCHWEGO® foam 6390 a silicone emulsion with a good knock down effect and chemical stability.

SCHWEGO® foam 6391 an emulsion of different active substances. Application fields are glossy paints, matt to satin-gloss emulsion paints, industrial coatings.

SCHWEGO® foam 6325 is based on native raw materials. Application areas are paints with medium to high PVC. SCHWEGO® foam 6325 has no negative influence on the gloss properties of the paint.

SCHWEGO® foam 8333 is a polymere type. Using areas are high gloss paints, wood coatings, industrial coatings, aqueous 2 pack polyurethane systems and parquet floorings. Furthermore in emulsion paints free of VOC.

SCHWEGO foam® 8336 is a silicone oil defoamer for wood coatings, stains, parquet floorings, printing inks, industrial coatings and UV coatings.

Further information from our defoamer:

|

Produkt |

free of silicone oil |

VOC ISO 11890-1 (calculated) |

solvent-based systems |

Aqueous systems |

Solvent-free |

UV - systems |

Characteristics |

| BLISTER FREE 3 | • | 26,1% | XX | X | X | Highly compatible, improved leveling |

|

| BLISTER FREE 45 | • | 67,7% |

XX | X |

X |

Curtain coatings, very quick deaeration |

|

| BLISTER FREE 54 | • | 6,0 % | XX | XX |

High gloss systems, improves leveling | ||

| BLISTER FREE 55 | • | 76,0 % | X |

XX |

Very good deaeration, despatch of craters and pinholes |

||

| BLISTER FREE 56 | • | 51,4 % | XX | X | X | XX | UV – systems, improved leveling |

| BLISTER FREE 66 | |

84,5 % | XX | XX |

PE–systems, uniform leafing from wax | ||

| BLISTER FREE 75 | • | 76,0 % | XX | X |

X | NC – Coatings, Acid curing systems, furniture coatings |

|

| BLISTER FREE 77 | • | 90,0 % | XX | XX |

PE – Coatings, FDA – approval | ||

| BLISTER FREE 88 | 95,0 % | XX | XX |

PE-Coatings, biodegradable, FDA – approval |

|||

| SCHWEGO® foam 6303 | • | < 10,4 % | XX | X |

X | Highly compatible, optimized the leveling | |

| SCHWEGO® foam 6305 | < 0,1 % | XX |

Universal, prevent micro – and macro foam, no influence on the gloss |

||||

| SCHWEGO® foam 6325 | • | < 0,1 % | XX |

Carrier: natives oil, emulsion paints, plaster | |||

| SCHWEGO® foam 6351 | • | 90 % | XX |

X |

X | X | Very good efficiency to prevent micro foam |

| SCHWEGO® foam 6354 | • | 0 % | X |

X |

X | X | Very good efficiency to prevent macro foam, 2 K-PUR - Coatings |

| SCHWEGO® foam 6360 | • | 0 % | XX |

XX |

Solvent-free systems, UV – Coatings, no haze | ||

| SCHWEGO® foam 6361 | • | 0 % | XX |

XX | Solvent-free systems, UV–Coatings, no haze | ||

| SCHWEGO® foam 6375 | • | 6 % | XX |

X | X |

Long oil alkyds, printing inks | |

| SCHWEGO® foam 6388 | 1,6 % | XX |

X | XX |

UPE – systems, highle compatible | ||

| SCHWEGO® foam 6390 | 0 % | XX |

High gloss paints, emulsion paints, Industrial coatings, FDA-approval |

||||

| SCHWEGO® foam 6391 | < 0,2 % | XX |

Universal, very good efficiency against micro foam |

||||

| SCHWEGO® foam 8013 | 18,6 % | XX |

Aqueous 2 pack polyurethane paints, emulsion paints, adhesives |

||||

| SCHWEGO® foam 8325 | < 0,1 % | XX |

Emulsion paints, plaster, silica formulations | ||||

| SCHWEGO® foam 8333 | • | 0,6 % | XX |

X | X | Aqueous 2pack polyurethane paints, parquet floorings, high gloss paints, stains, clear coatings |

|

| SCHWEGO® foam 8336 | 0,5 % | XX |

X | XX |

Clear coatings, parquet floorings, High gloss paints, UV-systems, printing inks, biodegrable,FDA - approval |

||

| MITTEL S | 98,0 % | XX |

X |

X | Stoving paints, 2pack – formulations, printing inks, NC-paints, deco-coatings, floor coatings based on epoxy, FDA -approval, biodegradable |

XX - especially recommend, X - recommend